GIS determines root cause and solution for polymer and plastic materials failure analysis, providing problem-solving and solutions for failure related problems. Polymer properties and characteristics are measured to help determine why polymeric materials fail. The polymer laboratories are staffed by scientists and technicians with significant expertise in multi-disciplinary failure investigation applications.

- MOBILE: 0423 735 578/ PHONE: 03 9748 8983

- ADDRESS: Unit 2, 162-172 Old Geelong Rd, Hoppers Crossing, VIC 3029

- Email: lab@gisteks.com

Failure Analysis

Failure Analysis of Polymer

The common failure analysis for polymer include:

• Additives in Polymers and Elastomers

• Contaminants and Inclusions

• Mechanical Failure

• Chemical Attack

• Trace Chemical Analysis

• Oxidative and Degradation

• Failure of Fibre-reinforced Composites

• Weathering

• Polymer Discoloration

• Environmental Stress Cracking

• Polymer Odour, Tainting and Outgassing problems

• Adhesion problems with Polymers and Interfaces

Approaches for Failure Analysis

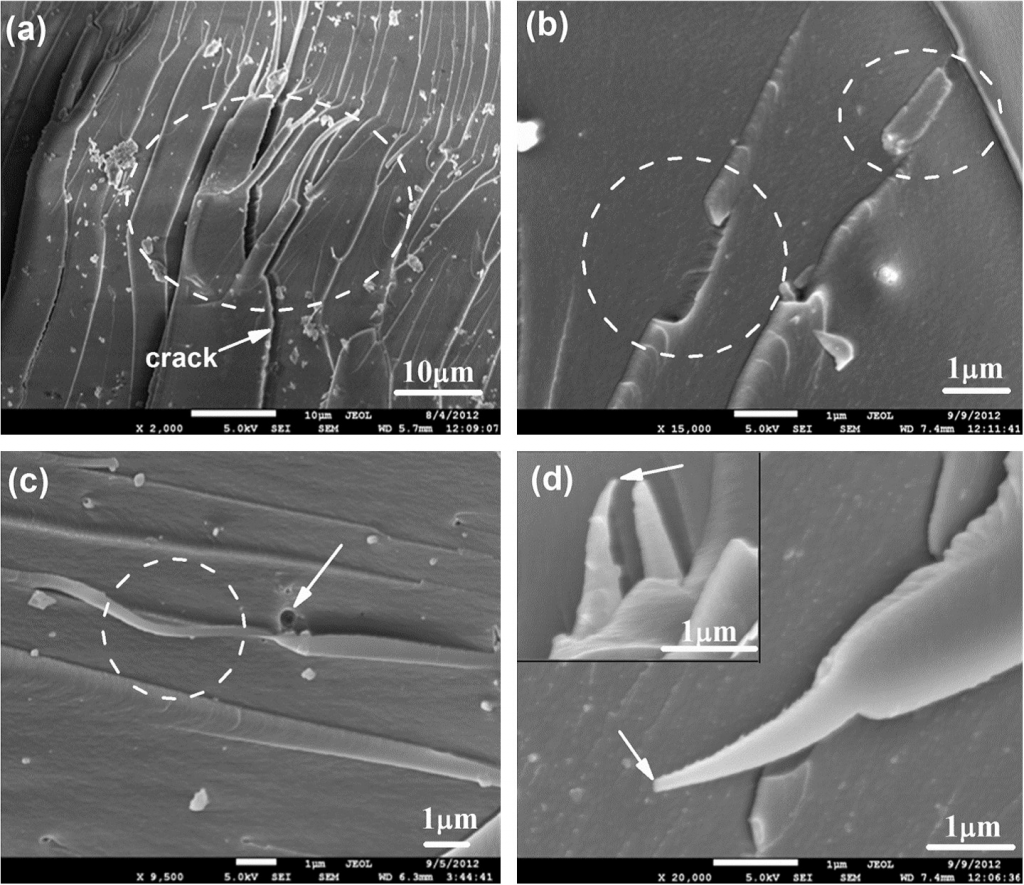

1. Failure analysis often begins with an examination of the part, often using microscopic methods. For a physical failure, the crack surface can provide clues about the nature of the failure, such as whether the part underwent brittle or ductile failure, or whether it was the result of environmental stress cracking (ESC).

2. If chemical attack is suspected, chromatographic techniques may be applied to look for the presence of a solvent or other compound that could break down the part. Additionally, if certain types of degradation are suspected, analysis of the additives by chromatographic methods may be carried out.

3. Molecular weight analysis of good and bad parts may be applied to confirm that degradation is occurring.

4. Thermal analysis (DSC) can be used to look at differences in thermal history which could manifest in variations in crystallinity. Crystallinity can affect mechanical properties.

5. Nuclear Magnetic Resonance Spectroscopy (NMR) may be applicable for materials that are blends or copolymers to verify the correct ratios of components.

6. In some cases, mechanical testing may be carried out to confirm the suspected failure mode. In addition, verification of fillers may also be important.

Failure analysis work is carried out in support of customers’ own investigations, customer complaints or liability disputes, or as part of complex litigations cases